Introduction à la formation sur la maintenance aéronautique

| Site: | Aeronautical Maintenance Training EASA Part-66 |

| Cours: | Aeronautical Maintenance Training EASA Part-66 |

| Livre: | Introduction à la formation sur la maintenance aéronautique |

| Imprimé par: | |

| Date: | mercredi 21 janvier 2026, 22:47 |

Description

Cliquez et parcourez la table des matières qui apparaît à droite.

1. Visites obligatoires de maintenance des avions

Les constructeurs (Boeing et Airbus, et les autres) imposent aux compagnies des visites techniques régulières obligatoires, baptisées A, B, C et D, correspondant à un nombre donné d’heures de vol ou à une durée de vie estimée d’un appareil donné. Ces visites de maintenance des avions s’effectuent selon un rythme déterminé par les constructeurs.

La visite de type A intervient environ tous les mois ou toutes les 500 heures de vol. Elle est effectuée généralement en une nuit dans une enceinte de l'aéroport.

La visite de type B se fait environ tous les 3 mois. La visite est généralement effectuée en une nuit dans une enceinte de l'aéroport. Tous les systèmes, comme les équipements de secours et les blocs de navigation, sont examinés.

La visite de type C se fait environ tous les 12-18 mois ou en fonction d’un nombre précis d'heures de vol effectives défini par le constructeur. Cette visite dure une semaine. L'appareil étant mis hors service, il faut beaucoup d'espace, le plus souvent un hangar de maintenance1. La structure entière de l'avion est passée au peigne fin.

La visite de type D est également connue sous le nom de « grande visite » ou de « visite de maintenance lourde ». Elle s’effectue environ tous les 4-5 ans. Elle nécessite plus de temps et d’espace que les autres types et doit être exécutée dans un hangar de maintenance. Elle dure au minimum 2 semaines, parfois jusqu’à 2 ou 3 mois en fonction du type d’appareil, de son âge et du nombre d’heures de vol. Les compagnies en profitent généralement pour installer les dernières améliorations apportées par les constructeurs. L’appareil est alors immobilisé au sol pour une longue période, au cours de laquelle tous ses composants sont inspectés et réparés si nécessaire.

2. Règlements de l'AESA (Agence européenne de la sécurité aérienne)

Les visites décrites précédemment nécessitent un personnel formé aux différentes tâches et au niveau technique adéquat à chacune de ces tâches.

Cela est décrit dans le Règlement (CE) N° 1321/2014) du 26 novembre 2014, modifiant le règlement (CE) N° 2042/2003) du 20 novembre 2003 relatif au maintien de la navigabilité des aéronefs et des produits, pièces et équipements aéronautiques, et à l'agrément des organismes et des personnels participant à ces tâches :

- Maintien de la navigabilité : Annexe I - Part M

- Agrément des organismes de maintenance : Annexe II - Part 145

- Personnel de certification : Annexe III - Part 66

- Agrément d'organisme de formation - personnel de certification : Annexe IV - Part 147

3. Part-147 Organisations

Seuls les organismes de formation peuvent délivrer une LMA (licence de maintenance d'aéronefs), qui sont décrits dans l'annexe 4 de l'AESA, Part-147, "Agréments des organismes de formation à la maintenance".

La Part-147 décrit les exigences auxquelles doivent répondre les organismes qui souhaitent être agréés pour dispenser des formations et des examens.

Les directives de la Part-147 traitent des exigences suivantes :

- Personnel,

- Équipement et cours d'instruction, Installations,

- Procédures de formation et système qualité,

- Examens.

4. Licences de maintenance d'aéronefs Part-66

Le personnel de certification autorisé conformément à la Part-66 pourra détenir une autorisation de certification dans une ou plusieurs des catégories suivantes :

- Cat. A (mécanicien certificateur de maintenance en ligne) ;

- Cat. B1 (technicien de certification en maintenance - mécanique) ;

- Cat. B2 (technicien de certification en maintenance - avionique) ;

- Cat. B3 (technicien de certification en maintenance - avion léger).

4.1. Les différentes licences Part-66

Les licences de catégorie A ne permettent d'effectuer que des tâches simples, telles que le changement d'une roue pour la partie mécanique, ou le changement d'une ampoule pour la partie électrique.

Les personnels de catégorie A travaillent généralement sur des avions en ligne, dans les aéroports.

Les licences des Catégories B sont destinées à former les mécaniciens qui effectuent l'entretien dans les centres de maintenance agréés PART-145. Ces personnels peuvent être utilisés pour l'entretien courant, l'inspection ou dans des rôles de supervision.

Le personnel de certification autorisé conformément à la Part-66 pourra détenir une autorisation de certification dans une ou plusieurs des catégories suivantes :

-

Cat. A (Mécanicien de certification de maintenance en ligne) :

Une licence de maintenance d'aéronefs permet à son titulaire de délivrer des certificats de remise en service à la suite d'une maintenance en ligne programmée mineure et d'une rectification simple des défauts dans les limites des tâches spécifiquement approuvées sur les règlements PART-145.

Les licences de catégorie A comprennent les sous-catégories suivantes :- A1 : Avion à turbine ;

- A2 : Avion à pistons ;

- A3 : Hélicoptère à turbine ;

- A4 : Hélicoptère à pistons.

-

Cat. B1 (technicien de certification d'entretien - mécanique) :

La licence d'entretien d'aéronefs B1 permet à son titulaire de délivrer des certificats d'autorisation de remise en service et d'agir en tant que personnel de soutien B1 suite à :

- des travaux d'entretien effectués sur la structure, le groupe motopropulseur et les systèmes mécaniques et électriques de l'aéronef,

- des travaux sur des systèmes avioniques ne nécessitant que des tests simples pour prouver leur aptitude au service et ne nécessitant pas de dépannage.

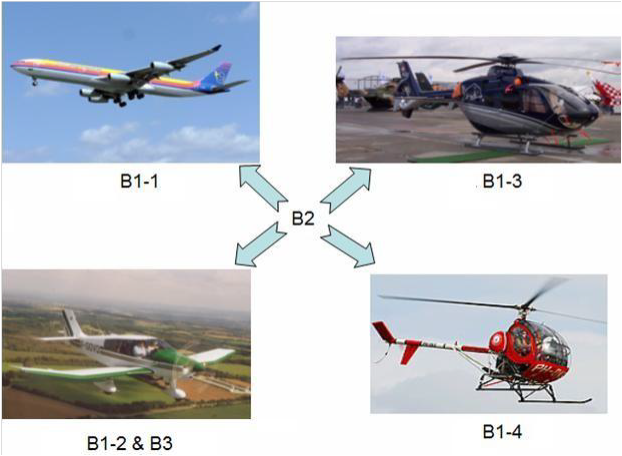

Les licences de la catégorie B1 comprennent les sous-catégories suivantes :

- B1.1 : Avion à turbine ;

- B1.2 : Avion à pistons ;

- B1.3 : Hélicoptère à turbine ;

- B1.4 : Hélicoptère à pistons.

La catégorie B1 comprend la sous-catégorie A correspondante.

-

Cat. B2 (Technicien de certification de maintenance - Avionique) :

- communication/navigation (com/nav),

- instruments,

- vol automatique,

- surveillance,

- systèmes de la cellule.

-

Cat. B3 (Technicien de certification en maintenance - avion léger) :

La licence B3 est applicable aux avions non pressurisés à moteur à pistons de 2 000 kg de masse maximale au décollage (MTOM) et moins.

La catégorie B2 concerne toutes les autres catégories

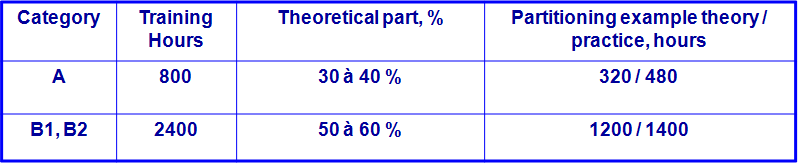

4.2. Volume d'heures de formation de base Part-66

Volume d'heures de formation typique pour des personnes sans AUCUNE expérience :

- Les licences A, B1, B2 doivent être validées dans un délai maximum de 5 ans après la formation.

- Tous les modules doivent être validés pour obtenir la licence.

- L'enchaînement et le contenu des modules dépendent de la catégorie (A, B1, B2) et/ou de l'aéronef (avion/hélicoptère, turbine/piston).